PTFE is known for it’s stability and resistance to many chemicals. … This makes it a very versatile material, and we mould, form and machine parts in this material.

Generally, PTFE is processed into semi-finished shapes with compression or iso-static moulding techniques. The PTFE resin in the form of a powder (pure or blended with fillers) is compressed into a preform mould at ambient temperature. After removal from the mold, the preformed rod or tube is heated in an oven and sintered.During this process it gains its cohesive strength for end use. For high-volume parts production, PTFE shapes are formed into continuous lengths by means of ram-extrusion. A hydraulic ram moves back and forth, pushing and compressing PTFE powder through an extrusion profile while it is being heated and sintered at the same time.From the semi-finished rod or tube, the finished PTFE seals are produced by precision-machining.

PTFE powder, semi-finished shape and final machined product

PTFE powder, semi-finished shape and final machined product

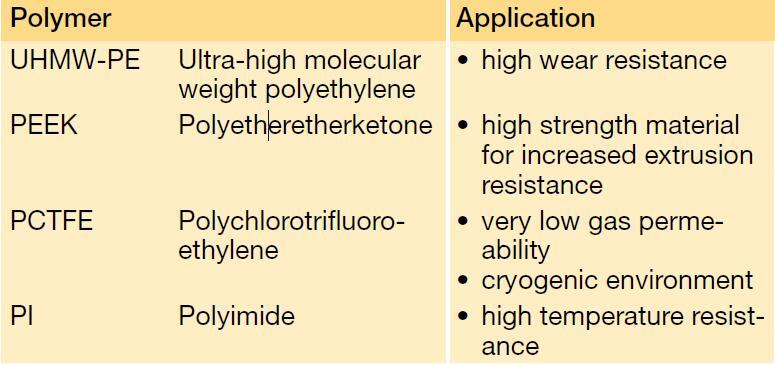

Other typical polymeric materials and their application range:

Post time: Dec-08-2018